PET Strap

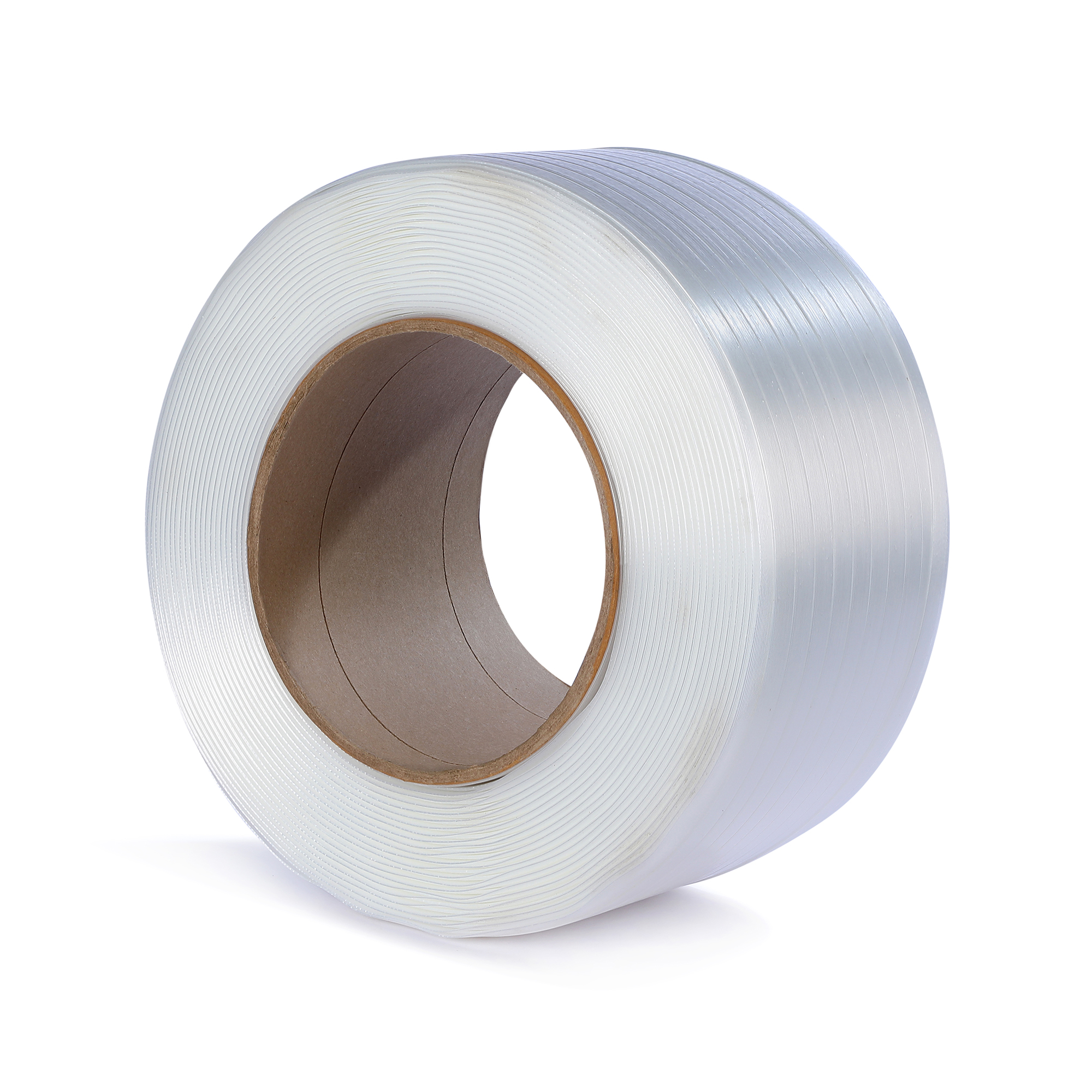

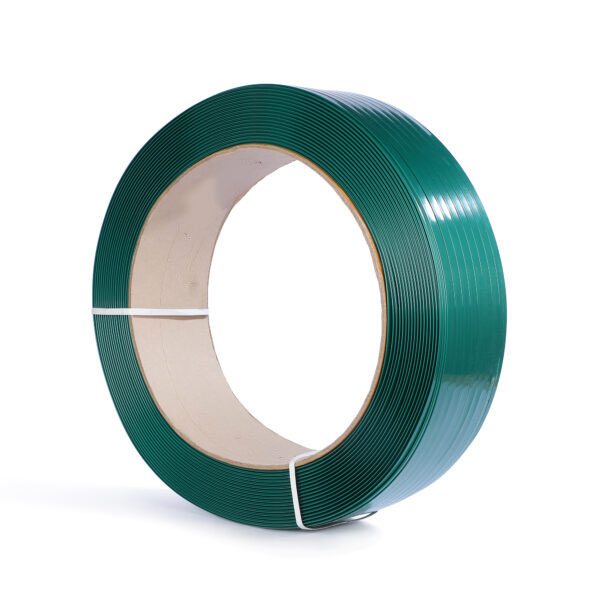

PET STRAP (Polyethylene Terephthalate Strap)

- Safe and logical alternative strap to replace steel strapping.

- Used for Medium to Heavy duty Applications.

- Can Withstand temperature upto 75 degree celsius without losing its characteristics.

PET Strap is classified into two types based on its strapping surface.

- Plain

- Embossed

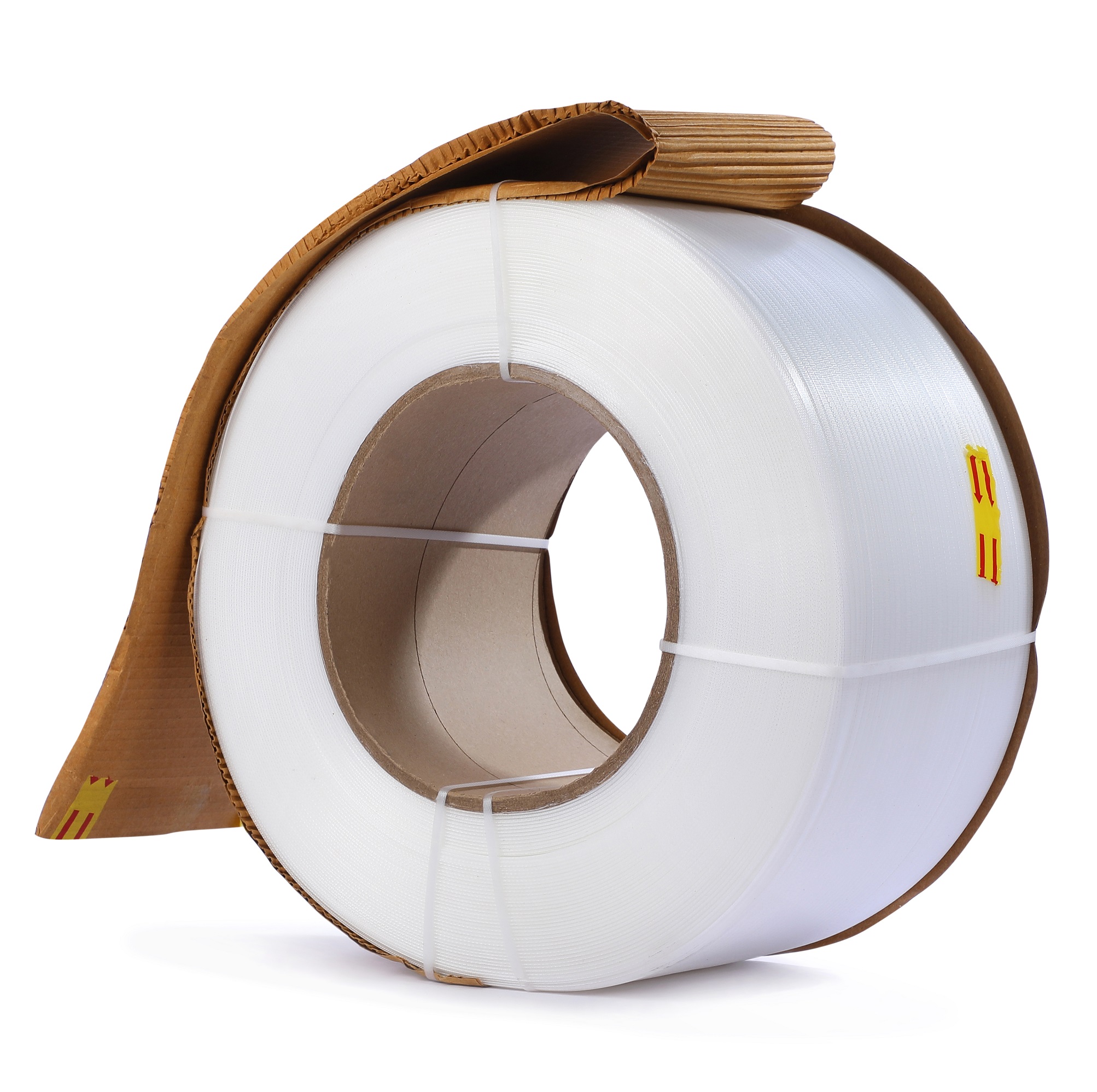

Plain PET Strap

- The Strapping surface is plain

- Ideal for medium to heavy duty application

- Suitable for coir bailing applications.

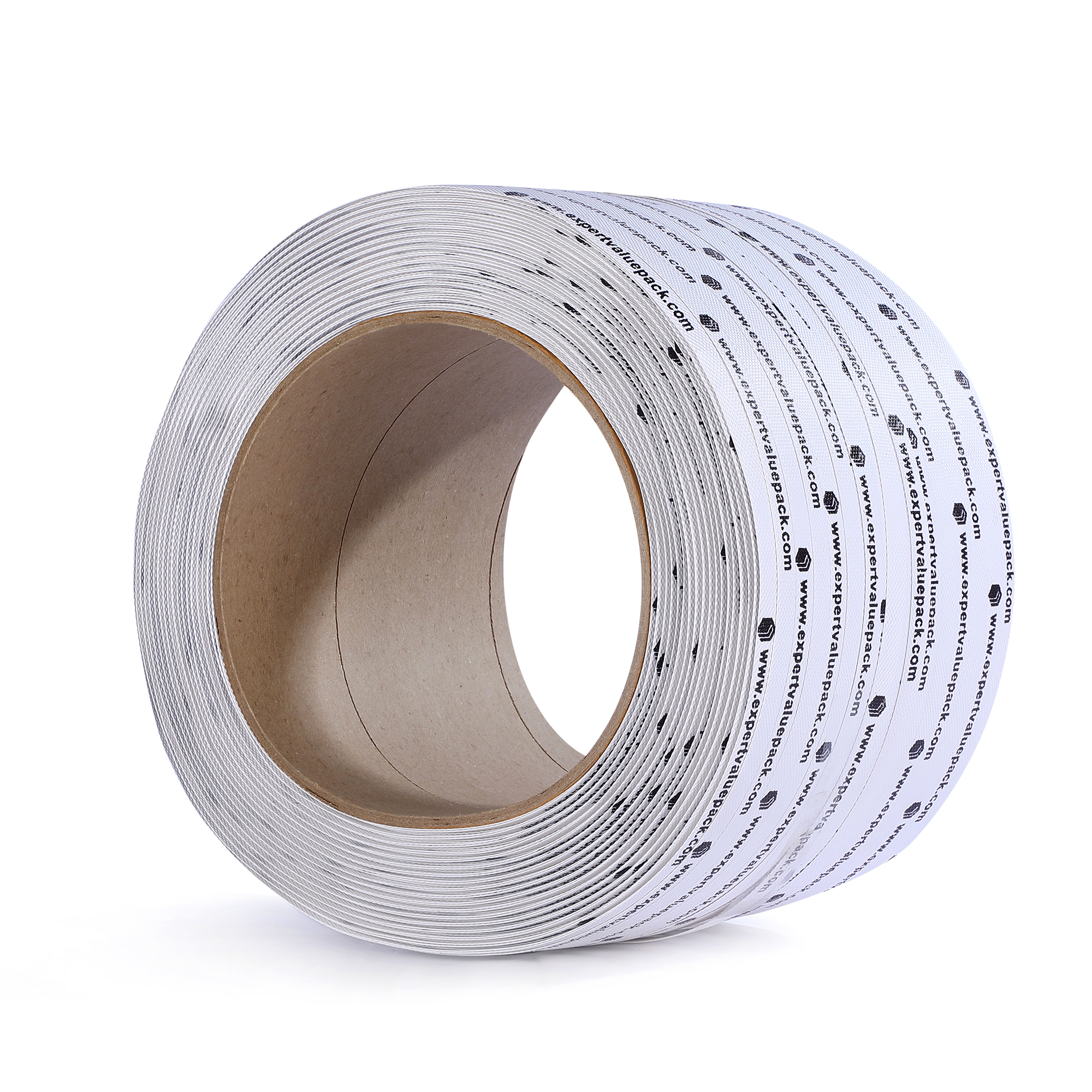

Embossed PET Strap

- The Strapping Surface is textured

- Ideal for Light to Medium duty application

- Suitable for all types of friction welding tools.

How to join both the ends of PET and PP Strap

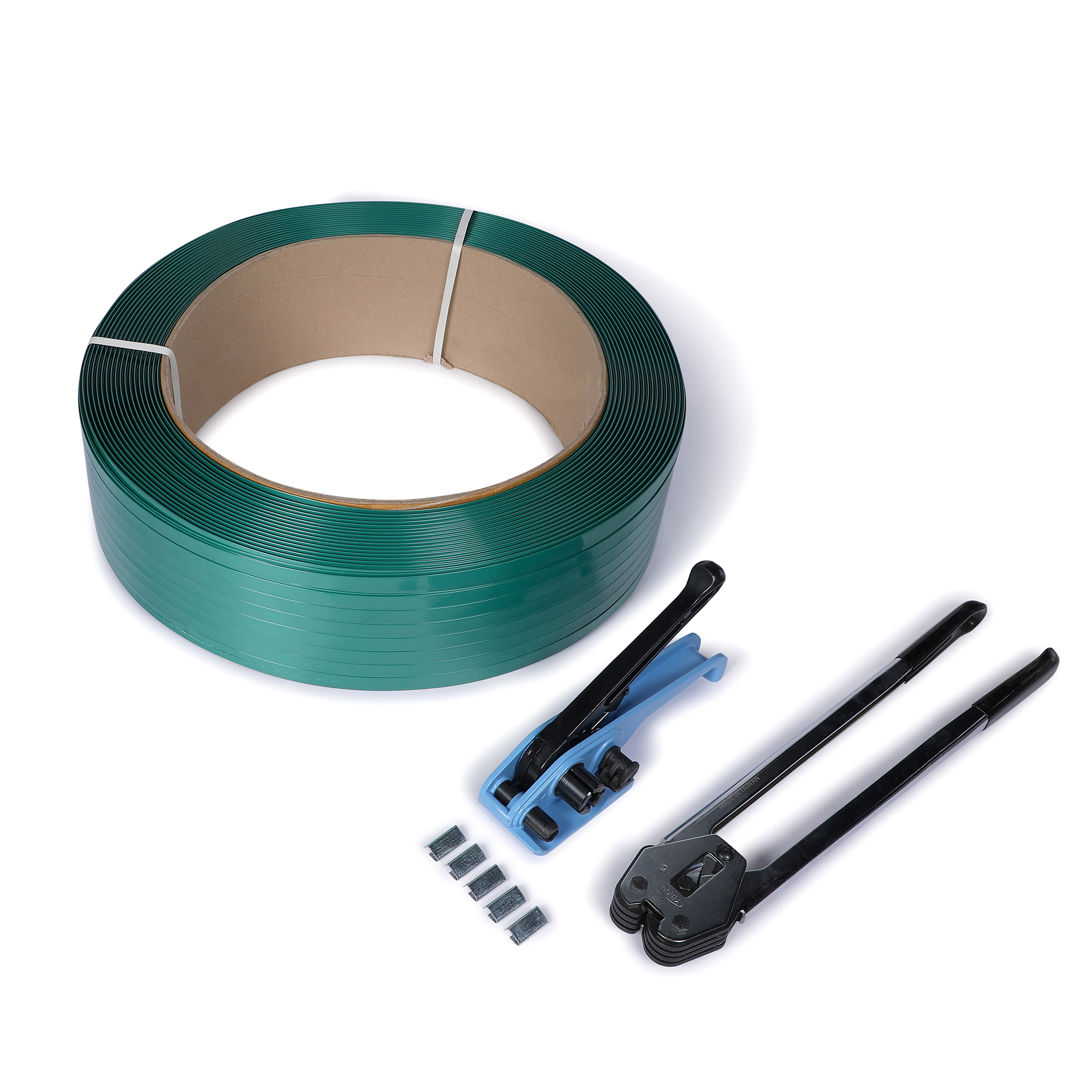

- Manual Strapping – Metal Seal with Manual Strapping tool is used to join both the ends (Attach Manual Sealed Picture).

- Friction Welding with Pneumatic Sealing Tool – Meant for baling application. Using the concept of friction welding, both the ends of the PET Strap is welded together. Compressed air at 6 bar pressure is mandatory to operate the pneumatic strapping tool.

- Friction Welding with Pneumatic Sealing Cum Tensioning Tool – Meant for fixed work station application.

- Friction Welding with Battery Powered Strapping Tool – Ideal for products which are heavy and not movable. Can be operated inside the container. The tool operates with battery power.

Specifications

| Width | 12 to 19mm |

| Thickness | 0.5 to 1.27mm |

| Break Load | 2300 to 9245 N |

| Elongation | 16% |

| Coil Dimensions | ID 400mm |

| Coil Weight | 20 to 25Kgs |

| Colour (Popular) | Green |

| Types | Plain, Embossed, Manual, Machine Grade, Printed, Plain, Colored, Pre-Cut |