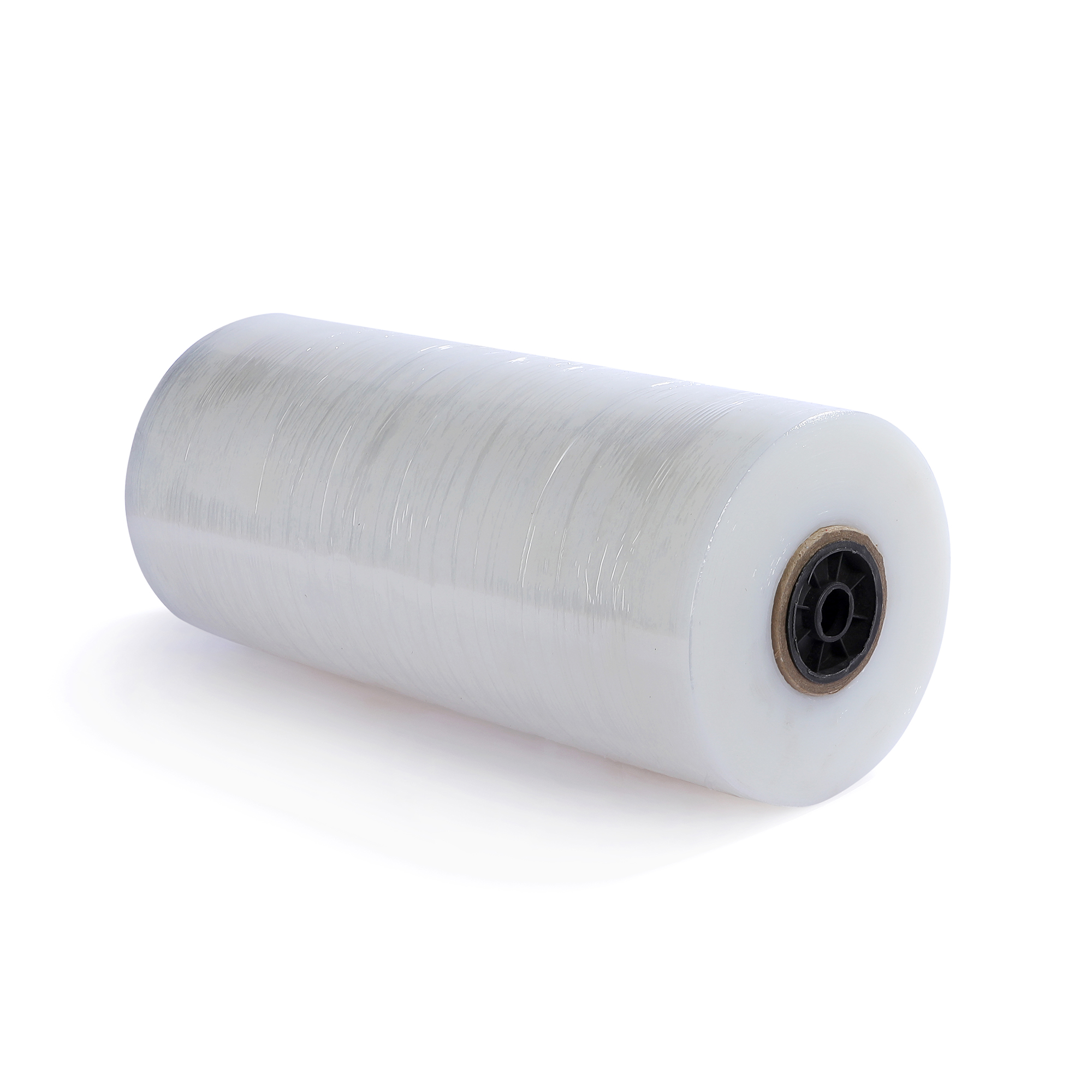

Stretch Film

Stretch Packaging wrap or Stretch Film is a highly stretchable plastic film that is wrapped around products. The elastic recovery keeps the product tightly bound.

It’s commonly used for pallet loads, but also can be used for smaller items.

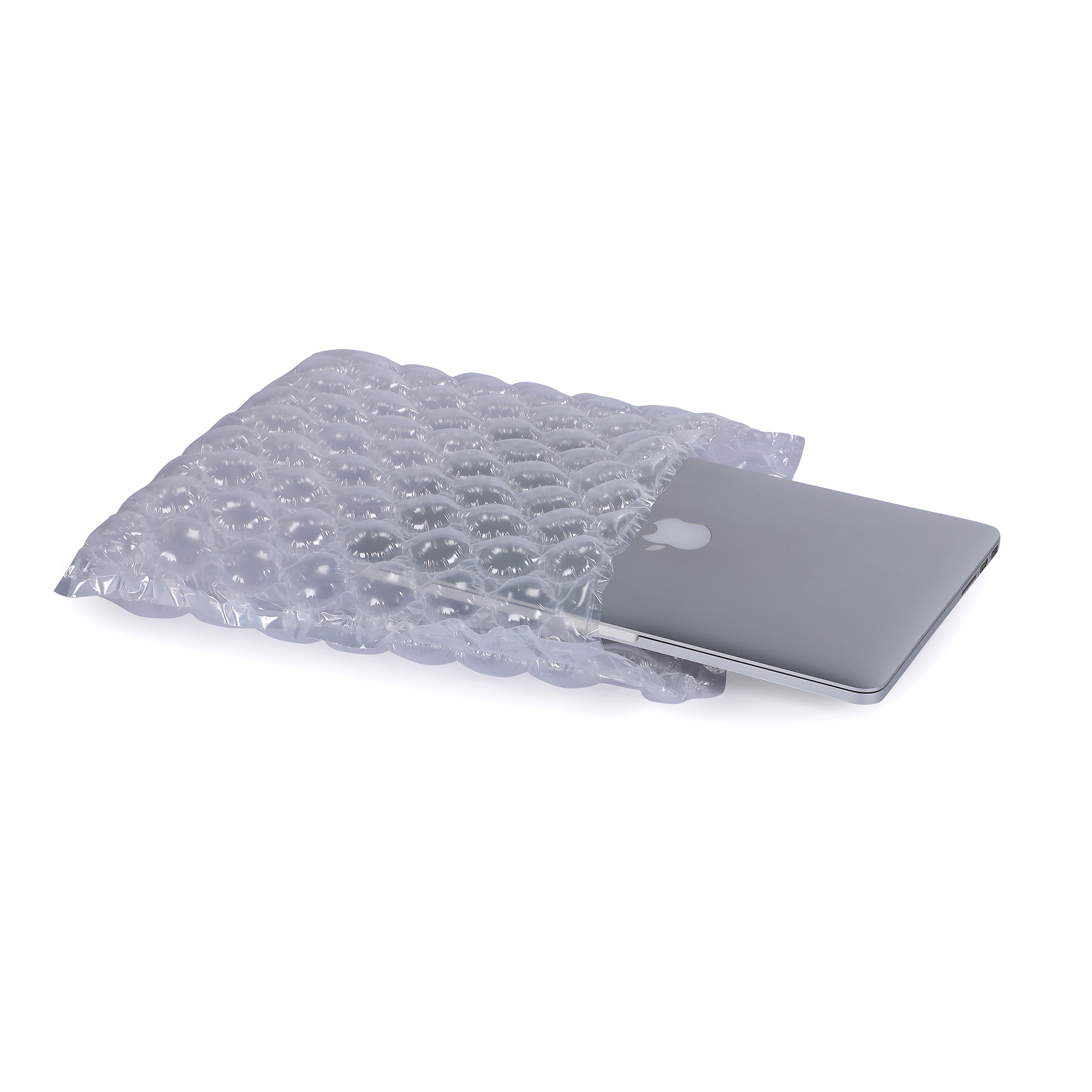

Functions

- Improved stability of products, forming a unit load

- Enables efficient handling

- Some degree of moisture and dust protection

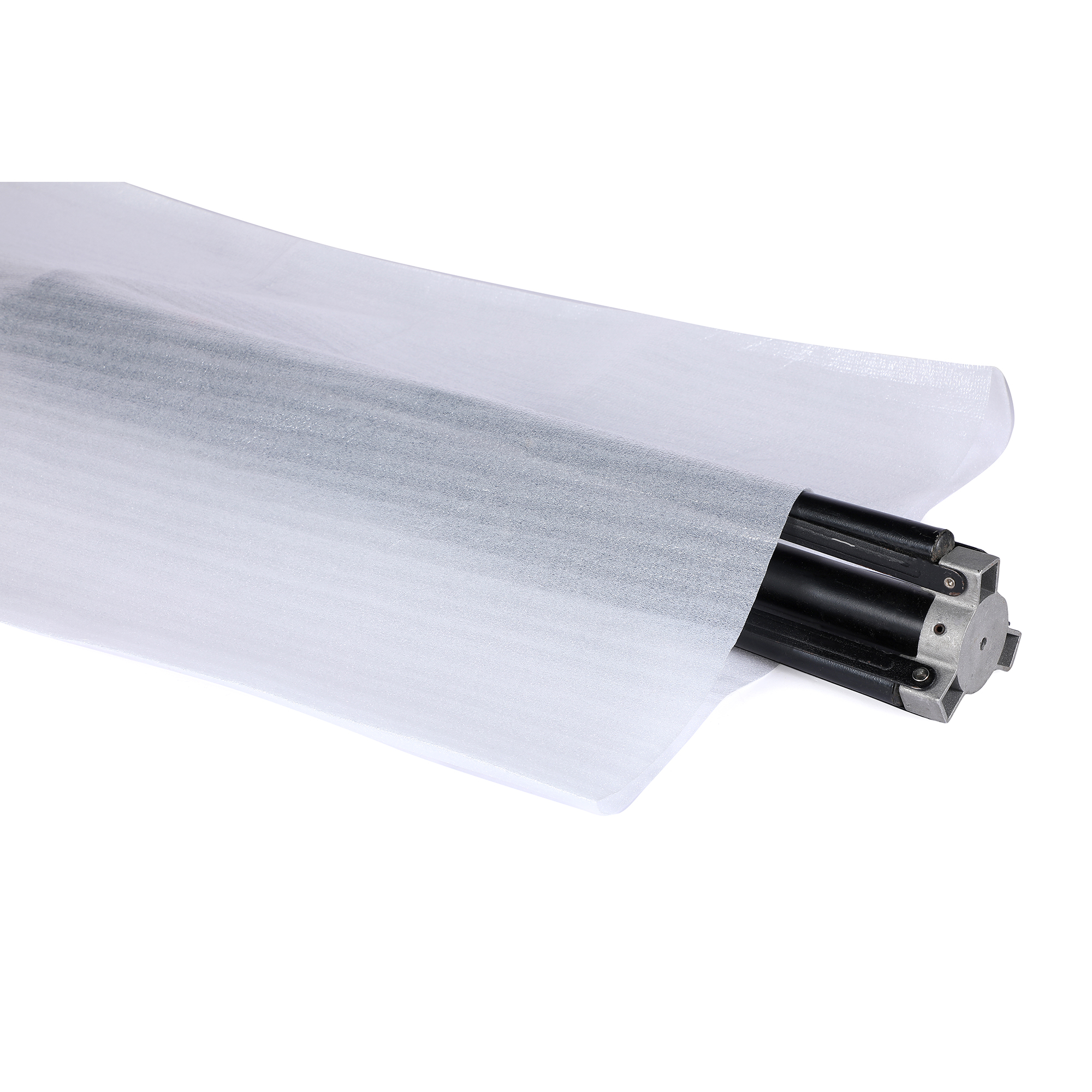

Equipment’s for Wrapping

- Manual Dispensers – Cap Type – Suitable for number of loads less than 10/day

- Manual Dispensers – Handle Type. Suitable for number of loads less than 10/day

- Stretch Wrapping Machines -Suitable for number of loads More than 15/day. Machine Stretch helps reduces the consumption, reduces the wastage, increases efficiency.

Type 1 – Turn Table Wrappers for Pallet Loads

Pallets are kept on the turn table. Stretch Film is tied with the pallet. Wrapping happens.

Type 2 – Rotary Arm Wrappers

Loads are kept stationery. Rotary Ann Wrappers, move around the load.

Type 3 – Orbital Wrappers

Feeding the load through a rotating ring of film.

Type 4 – Fully Automatic Stretch Wrapper

Involves conveyor belts and automatic machines to cut and seal the stretch wrap.

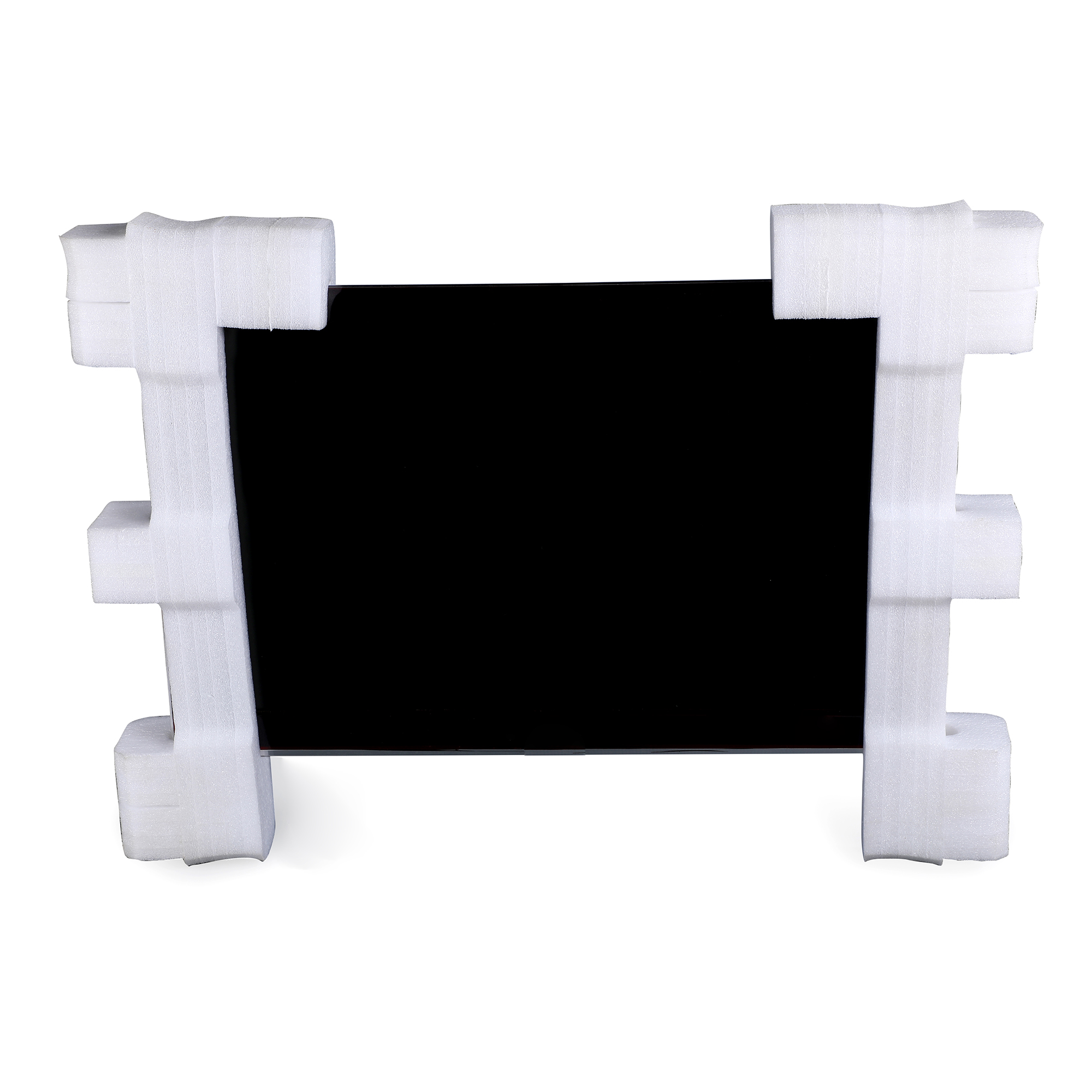

Type 5 – Box Wrapper

Individual Carton Boxes are wrapped in this